Precision, repeatability, traceability

We lock in fits, stabilize fabrics, and run QA checkpoints at every stage to ensure each production matches the sealed samples.

- ✓Pattern development matched to men's and boys' blocks

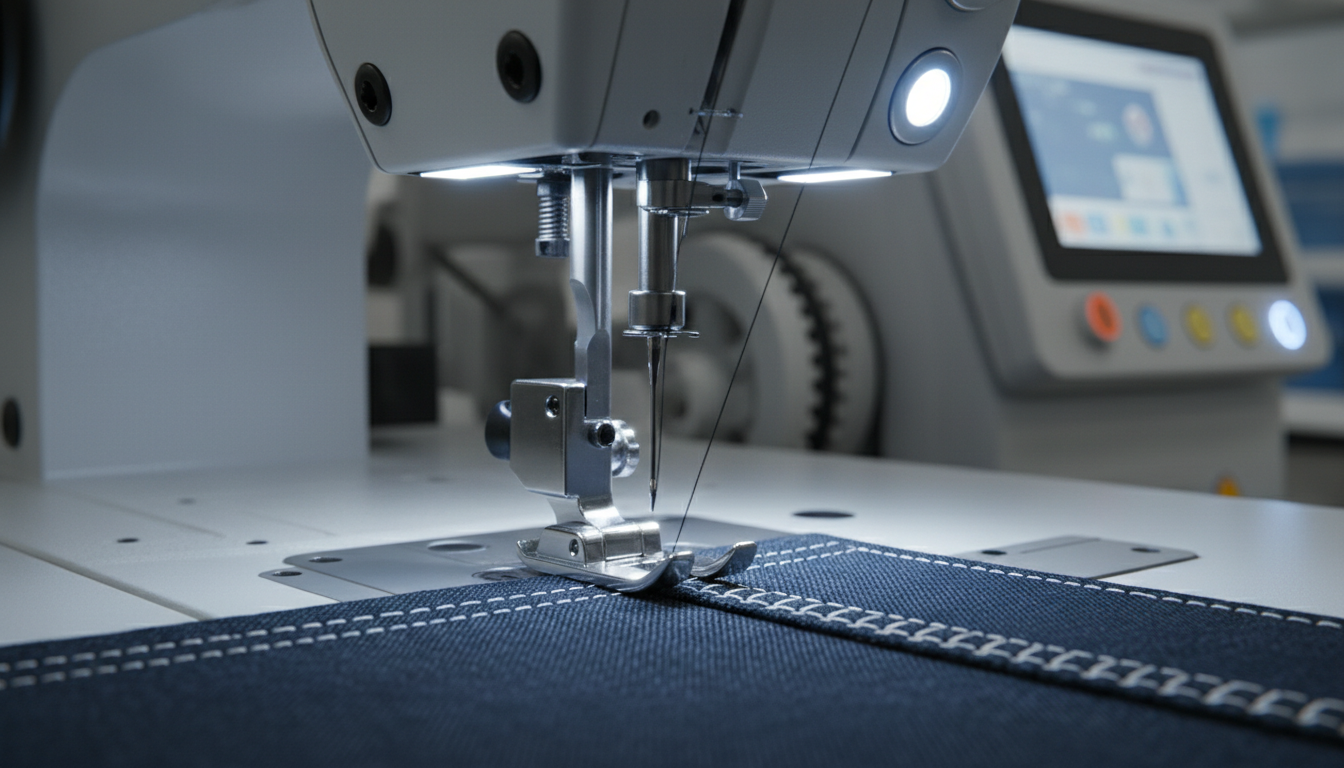

- ✓Automated cutting and reinforced seam construction

- ✓Inline QA, final inspection, pressed packing

Controlled stations for cutting, sewing, pressing, and finishing.

Five-stage workflow

Documented checkpoints to keep sizing, finishing, and timelines on track.

Fabric QA

Shrinkage and colorfast testing; roll inspection before cutting.

Pattern & Grading

Precise grading for men and boys; seam allowances and fusing maps defined.

Cutting

Automated spreading and cutting with marker efficiency; bundle labeling.

Sewing & Finishing

Reinforced seams, aligned patterns, clean inside binding, trim control.

Inspection & Packing

Measurement checks, pressing standards, defect thresholds, and branded packing.

Cutting & Sewing

Automated cutters, precision sewing lines, and pressing stations ensure accuracy and finish quality.

QA Framework

Inline checks for seams, pressing, measurements, and color; final inspection before packing.

Ready to ship

Hangers, folded packing, labels, barcodes, and carton markings aligned to partner requirements.

Consistent output for formalwear, casual, outerwear, and boys' garments.

| Checkpoint | Focus |

|---|---|

| Cutting | Marker efficiency, directional cutting, bundle labeling |

| Sewing | Seam strength, consistent SPI, aligned patterns |

| Pressing | Lapel roll, shoulder balance, crease stability |

| Packing | Labeling, folding/hanger spec, carton integrity |

Schedule a production review

Share your tech packs, target timelines, and fit expectations. We return with a production plan and QA path.